Our Story

The Wilson brothers come from a family of five children raised on a farm in Wisconsin. Their leadership skills were learned through 4-H and a strong work ethic via the daily care of livestock. Jack and Jim believe they inherited their Grandpa Wilson’s zest for entrepreneurship, and their Grandpa Armstrong’s creativity and ability to recognize and act on trends before others saw them.

In June of 2010, the trend they decided to focus on was the GREEN movement toward environmental sustainability. With that as the stimulus, Jack saw an opportunity to create something that would reduce the need for tape and grow the opportunities to reuse boxes. Working with Jim’s knowledge of business, law, and entrepreneurship, they formed Eco Latch Systems, LLC and produced the company’s first generation, extruded plastic Box Latch™. Who knew that a mere decade later Australia would be devastated by fires and 100-year floods would be occurring worldwide every few years

The ongoing research of the Box Latch™ brothers continued to show alarming statistics on the massive number of boxes headed to landfills and the costs incurred by companies to purchase new boxes. The fact that recycling requires nearly 70% of the energy and water required for a new box fuels their fire to reduce packaging waste.

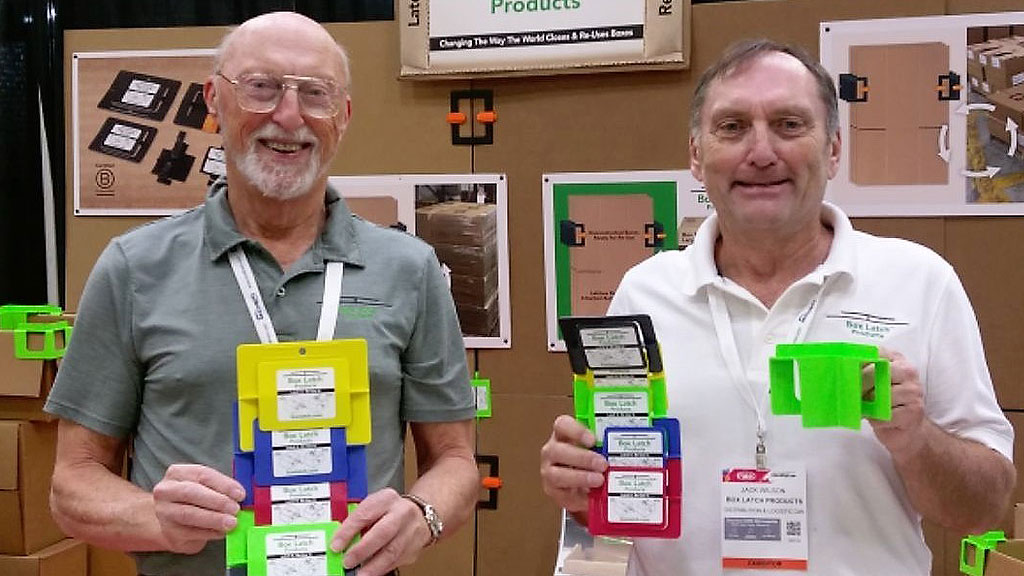

Aided by the brothers at Imperial Tool and Plastics in Greendale, WI, Jack and Jim have invented and produced three sizes of injection-molded Box Latches™. By listening to customers and applying their ingenuity, they now have a patent pending on the popular Corner Clip & Stack.

Purchases by distribution centers for the apparel giant, VF, (North Face, Lee, Wrangler, Nautica, Timberland & many more) have been a key to success. No company purchases 77,000 Box Latches, 41,000 anchors and 3,000 Clip and Stacks without a powerful financial and environmental ROI. Herman Goosens in Belgium and Petr Pavelcak in the Czech Republic saw this and capitalized on it.

People have always talked about the USA as the Land of Opportunity. The addition of handles that attach to Box Latches, a simplified Twist On latch and tamper evident tape will supplement the Box Latch™ line of products in 2020. The creativity, perseverance, positive attitude, and personal investment of two brothers whose ages average 73 and a 74-year old design engineer, Tom Wilcox, proves that the American Dream is alive and well at any age.